QUICK AND COST-EFFECTIVE METHOD

PIPE FREEZING SERVICE MAKES LEAK DETECTION AND MECHANICAL REPAIRS FASTER AND EASIER

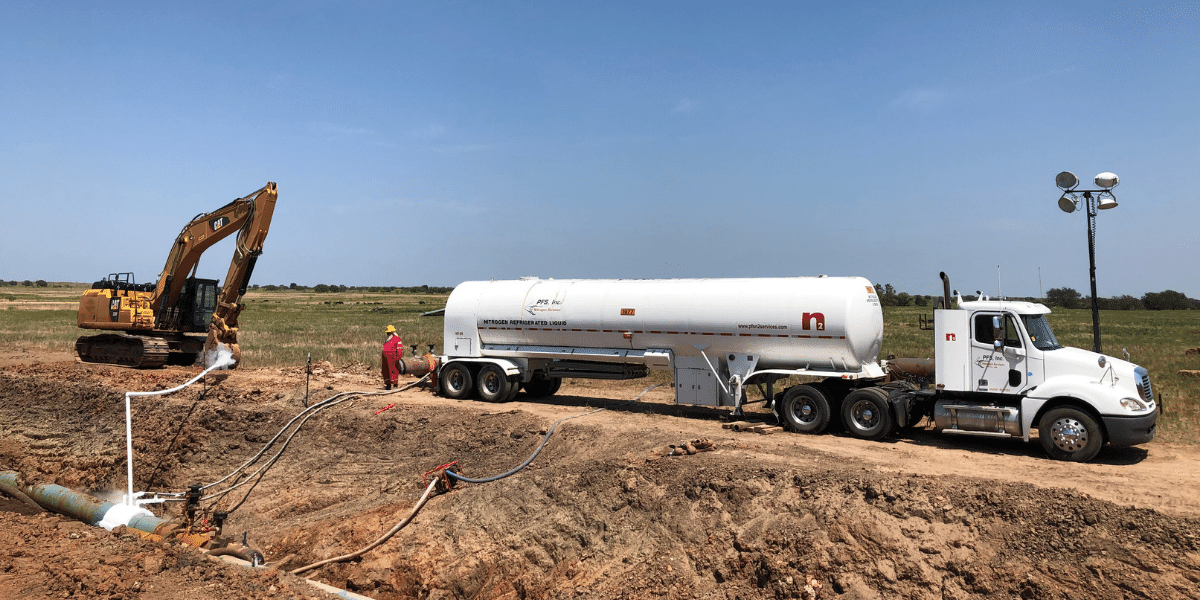

By controlling the liquid nitrogen to safely freeze stationary liquids in a section of a pipe that forms a ice plug on pipes up to 26” in diameter.

The proprietary pipe freezing techniques used by PFS, a sister company of N2 Solutions, has been proven to be the quickest and most cost-effective method available in today's market place, saving you both time and money.

What other technology allows you to eliminate the need to search half of the pipe segment in 3-8 hours depending on pipe size?

What other technology allows you to make repairs without removing the test medium from the entire line segment?

USES

![]() Leak Detection & Location

Leak Detection & Location

![]() Mechanical Isolation & Repairs

Mechanical Isolation & Repairs

![]() Fluid Cool Downs

Fluid Cool Downs

![]() Pneumatic Cool Downs

Pneumatic Cool Downs

![]() Solid Cool Downs

Solid Cool Downs

![]() Drying

Drying

HOW DOES PIPE FREEZING WORK?

By monitoring and controlling the surface temperature of the pipe, PFS can safely & accurately form an in-line ice plug, capable of withstanding up to 6,000 PSI.

We have conducted hundreds if not thousands of pipe freezes since 1993. Our proprietary and specialized jackets are engineered and fabricated in-house, backed by 27 years of experience.

PFS uses a systematic approach for the use of pipe freezing to detect hydro-static test leaks on buried pipelines that eliminates the need to walk miles of ROW as all other technologies currently require.

-2.png?width=550&height=441&name=Untitled%20design%20(8)-2.png)

PRODUCT EXPERIENCE

PFS also performs pipe freezing services inside hospitals & other buildings, marine vessels, chemical & other process plants or refineries for mechanical repairs without removing the fluids. If it’s tubular, full of freeze-able fluid & static, we can freeze it!

Independent laboratory studies and tests have analyzed the structural composition of pipes after freezing and have found no physical or chemical change in the matrix of the pipe due to the freezing process.

.png?width=600&height=300&name=1%20(3).png)

Pipe Freezing FAQ

-

How Do We Confirm a Successful Pipe Freeze?

We employ thermocouples and monitor the frost ring generated by our freeze jackets. Multiple checks and balances are in place to verify that the freeze is stable and effective.

-

Is Pipe Freezing Risky for the Pipe Itself?

No, our trained technicians ensure that proper spacing and pressure venting measures are in place to prevent cracking due to ice expansion.

-

Maximum Pipe Size for Freezing?

We can accommodate pipes up to 26 inches in diameter with our current freeze jacket inventory.

-

What is the Duration of a Freeze Plug?

As long as you need. Specify your required duration during the scheduling process.

-

Safety of Pipe Freezing?

Safety is a priority. We assess various factors like temperature, flow, and location before initiating any freeze to guarantee secure operation.

-

Geographical Coverage?

We primarily service the West Gulf, East Gulf, Southeast, and Northeast United States, although we have extended as far as California.

-

Temperature Range for the Freeze?

We utilize liquid nitrogen at around -320°F, but freeze temperatures are adjusted between -100 to -275°F depending on the product.

-

Does the Pipe Get Weaker?

On the contrary, controlled exposure to cryogenic temperatures essentially "heat treats" the pipe, making it stronger.

-

Prerequisites for a Successful Pipe Freeze?

Several conditions must be met, such as the liquid in the pipe being freezable and static.

-

When to Consider Pipe Freezing?

Our technology is versatile enough to be used for various repair or upgrade scenarios without requiring system shutdowns.

-

Impact of Wall Thickness?

Wall thickness doesn't impact the freeze. Our technology has shown no discernible damage to pipes of varying thicknesses.

%20(1).png?width=300&height=150&name=N2%20-(300%20x%20150)%20(1).png)